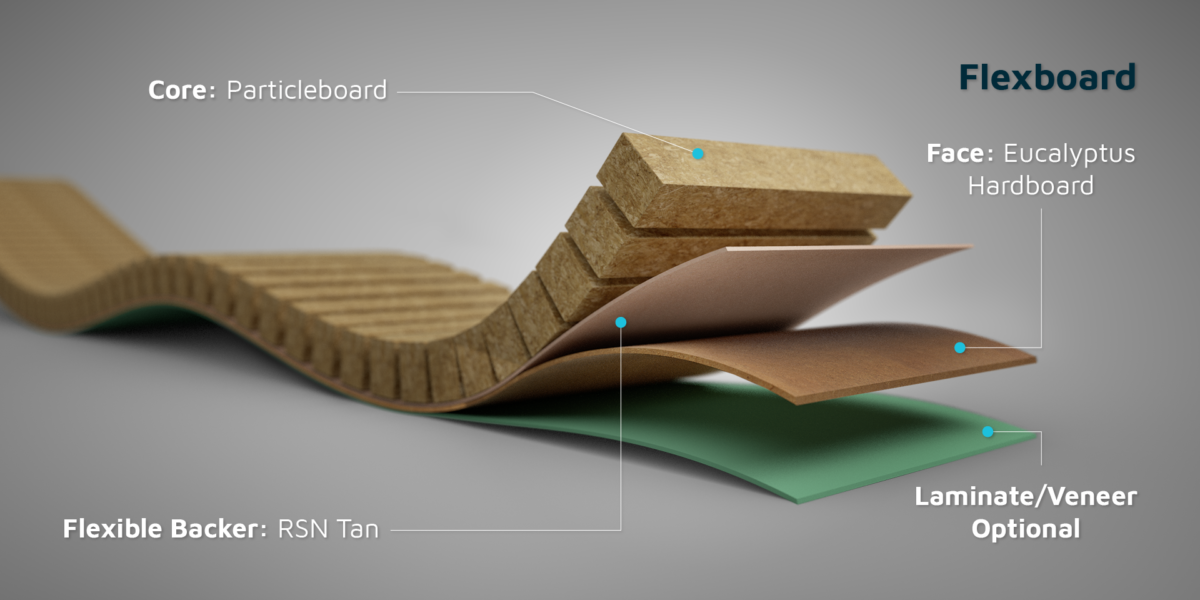

FLEXBOARD®

Our Flexboard flexible panel combines our unique base layer manufacturing process with a 0.080″ hardboard face to create a flexible and extremely stable base layer that allows easy attachment of high-pressure laminates, veneers, metals, and many other semirigid materials. When using Flexboard the decorative surfacing material is applied after the base material has been formed into the desired shape achieving an 8″ bending radius.

Face Materials

Eucalyptus Hardboard (Standard)

Core Materials

Particleboard (Standard)

Plywood

MDF

NAUF Particleboard

Fire Rated Option

NAUF Particleboard

Flame Spread Rating: ASTM E 84: Class A (Core Only)

Flame Spread Rating: ASTM E 84: Class A (Core Only)

Sustainable Options

NAUF Particleboard

Contains 100% recycled and/or recovered fiber in accordance with the Eco-Certified Composite standard CPA 4-11 fiber classifications

Contains 100% recycled and/or recovered fiber in accordance with the Eco-Certified Composite standard CPA 4-11 fiber classifications

Maximum Bending Radius

8"

Bending Radius

Bending radius is directly related to the decorative surfacing material being applied to Flexboard. While a smaller radius may be obtainable, it is best to test before proceeding.

Nominal Thickness

| 1/2" | 5/8" | 3/4" | 11/16" | ||

|---|---|---|---|---|---|

| Particleboard | |||||

| Plywood | |||||

| MDF | |||||

| NAUF Particleboard | |||||

Panel Sizes

| 48" x 120" | 48" x 96" | 96" x 48" | 120" x 48" | ||

|---|---|---|---|---|---|

| Particleboard | |||||

| Plywood | |||||

| MDF | |||||

| NAUF Particleboard | |||||

Decorative Surfacing Materials

High Pressure Laminates

Veneers

Metals

Paint

Adhesive Option for Lamination

Contact Adhesive

Recommended when using a J-Roller

PVA Glue

Recommended when using a Press Machine

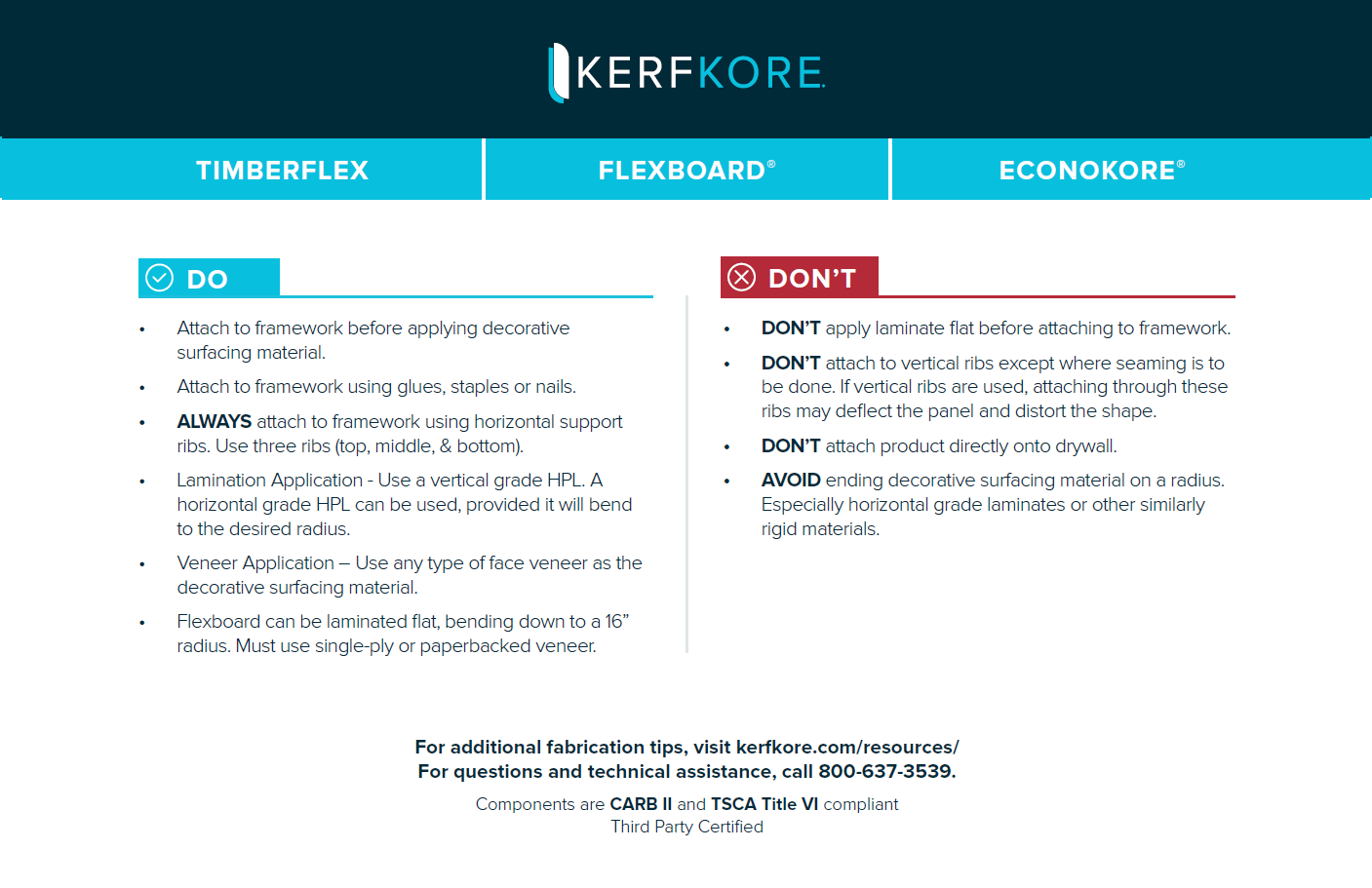

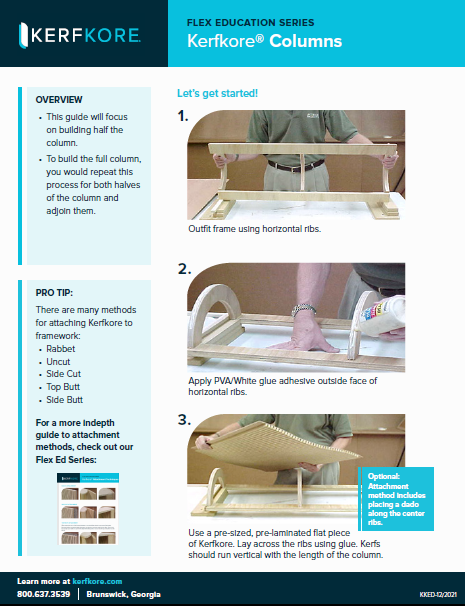

Attachment Methods

See Flexboard Flexible Panel Attachment Methods Guide