inspired design

simple solution

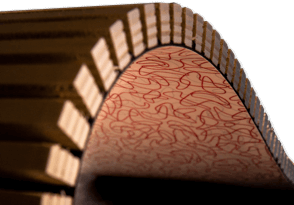

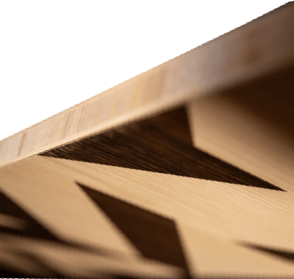

Lightweight and flexible architectural panels that provide a consistent and reliable result every time.see these products

Photo Credit: Cotton Global Disaster Solutions

what is

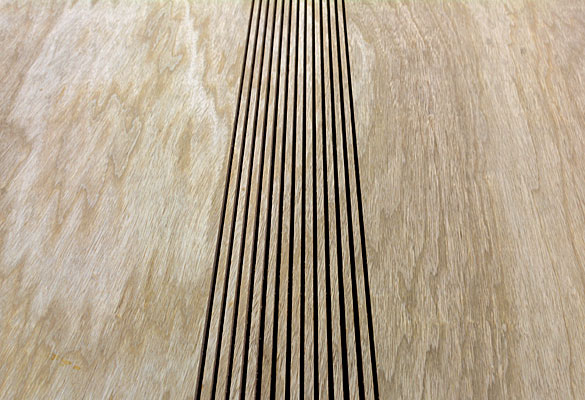

kerfkore?Kerfkore lightweight and flexible architectural panels are designed to reduce time and money spent on contour and large feature projects. Our lightweight panels are up to 80% lighter than traditional materials and our flexible panels reduce project time by up to 70% over traditional methods, no special tools required. Our precision design and process ensure consistency, stability and symmetry every single time.

BENEFITS OF

KERFKOREKerfkore panels require less surface prep, structural framework, materials, and installation time. Our flexible panels bend tighter, with more consistency and dimensional stability than traditional products. Our lightweight panels reduce weight up to 80% compared to plywood, particleboard, and MDF. No special tools, materials or installation steps are required. Additional services and custom options are available with most of our products. Simplify and streamline your process by using Kerfkore products.