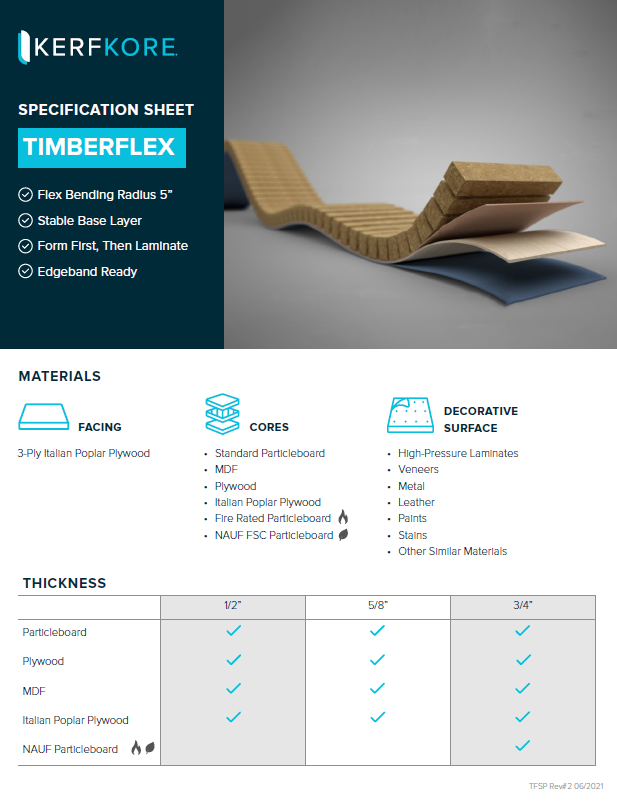

TIMBERFLEX

Our Timberflex flexible panel combines our unique base layer manufacturing process with our 1/8″ imported Italian Poplar Plywood Face to create a flexible and extremely stable base layer that allows easy attachment of high-pressure laminates, veneers, metals and many other semirigid materials. When using Timberflex, the decorative surfacing material is applied after the base material has been formed into the desired shape achieving a 5″ radius.

Face Materials

3-Ply Italian Poplar Plywood

Core Materials

Particleboard (Standard)

Plywood

MDF

Italian Poplar Plywood (Premium)

NAUF Particleboard

Fire Rated Option

NAUF Particleboard

Flame Spread Rating: ASTM E 84: Class A (Core Only)

Flame Spread Rating: ASTM E 84: Class A (Core Only)

Sustainable Options

NAUF Particleboard

Contains 100% recycled and/or recovered fiber in accordance with the Eco-Certified Composite standard CPA 4-11 fiber classifications

Contains 100% recycled and/or recovered fiber in accordance with the Eco-Certified Composite standard CPA 4-11 fiber classifications

Maximum Bending Radius

5"

Bending Radius

Bending radius is directly related to the decorative surfacing material being applied to Kerfkore. While a smaller radius may be obtainable, it is best to test before proceeding.

Nominal Thickness

| 1/2" | 5/8" | 3/4" | ||

|---|---|---|---|---|

| Particleboard | ||||

| Plywood | ||||

| MDF | ||||

| Italian Poplar Plywood | ||||

| NAUF Particleboard | ||||

Panel Sizes

| 48" x 96" | 96" x 48" | ||

|---|---|---|---|

| Particleboard | |||

| Plywood | |||

| MDF | |||

| Italian Poplar Plywood | |||

| NAUF Particleboard | |||

Decorative Surfacing Materials

High Pressure Laminates

Veneers

Metals

Paint

Stain

Adhesive Option for Lamination

Contact Adhesive

Recommended when using a J-Roller

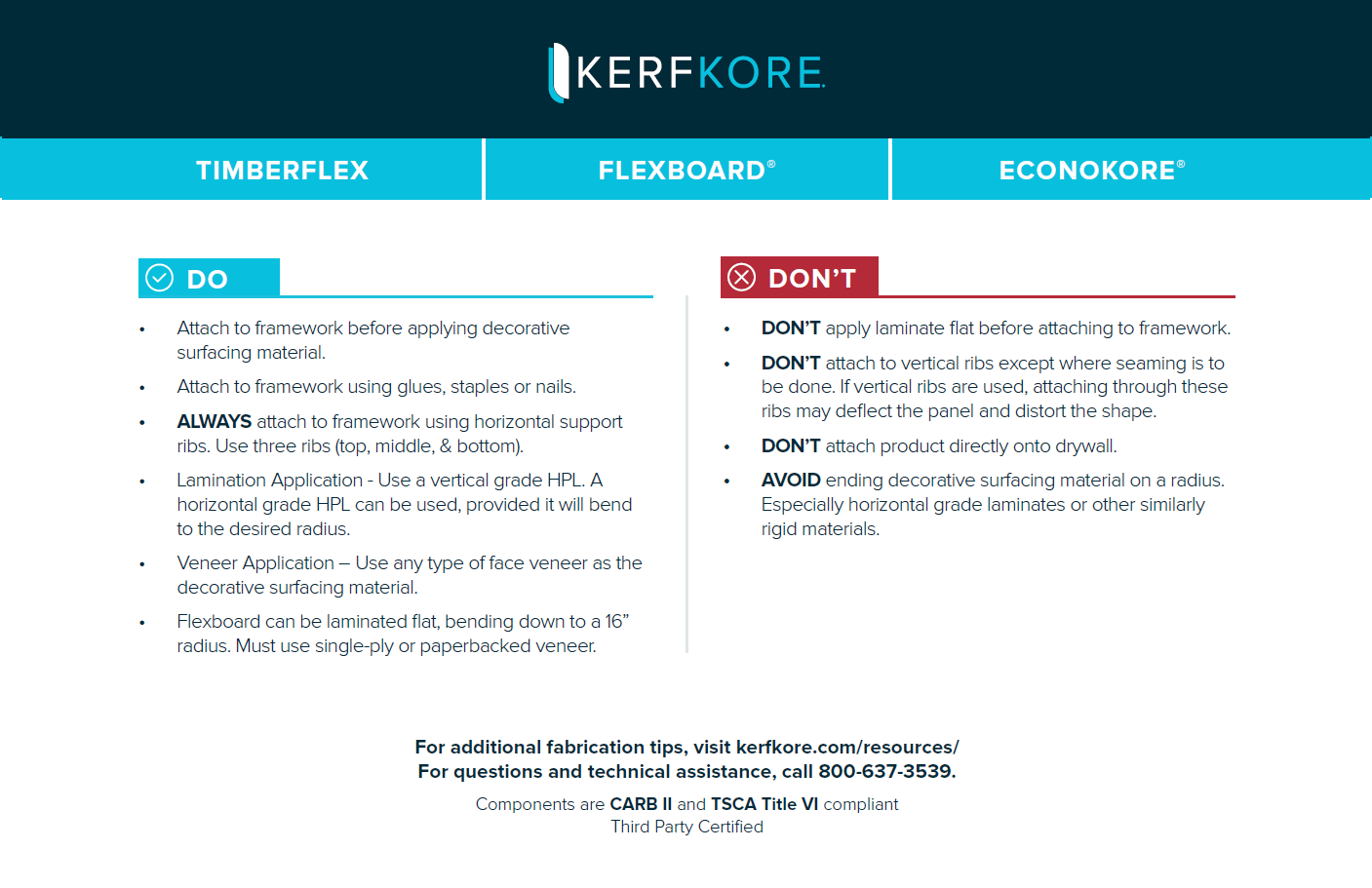

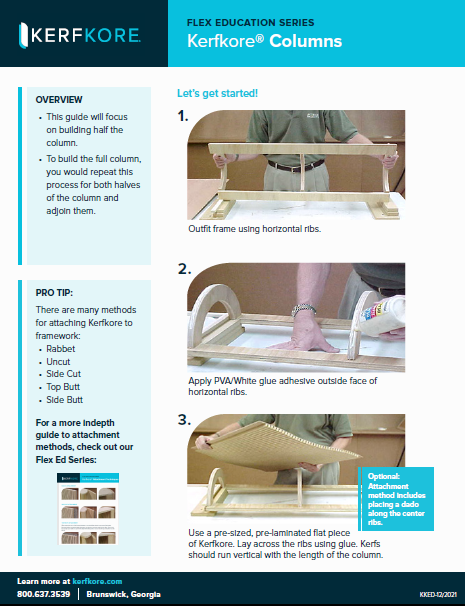

Attachment Methods

See Timberflex Flexible Panel Attachment Methods Guide